Silicone rubber keypads are a compelling option because they offer various benefits, ranging from aesthetic appeal to durability and customization options.

Durability

Silicone rubber keypads boast impressive durability. One of their key advantages lies in their resistance to temperature and humidity fluctuations, making them suitable for environments where traditional keyboards might falter. Whether it’s a scorching summer day or a humid workspace, silicone keypads maintain their functionality without compromising performance.

Moreover, silicone keypads come with top coatings such as epoxy, PU, or silicone that provide an extra layer of protection against abrasion and wear. This ensures that the keypad retains its pristine appearance and tactile feel over extended periods, even with frequent usage.

Customization Options

One of the standout features of silicone keypads is the abundance of customization options. Thanks to various top coatings and design elements, manufacturers, including King Epoxy Emblem Co Ltd, can tailor the keypads to meet specific design requirements and aesthetic preferences. Whether it’s a sleek, translucent silicone keypad serving as a diffuser or a colorful one, the possibilities are endless.

Furthermore, the design flexibility extends to tactile or linear design options, allowing users to select the typing experience that suits them best. Screen-printed texts and logos add a personalized touch, accommodating branding needs or user interface requirements effortlessly.

Enhanced Functionality

Silicone keyboards come with a range of design features to enhance functionality. From carbon contacts molded into solid round shapes to gasketed rubber designs that reduce water ingress, these keyboards are engineered to deliver optimal performance in various settings.

For applications requiring backlighting, silicone keypads can be manufactured with laser etching for precise illumination, ensuring usability in low-light conditions.

Additionally, the integration of light pipes through keypads enhances visibility and aesthetics.

Cost-Effective Solutions

Silicone keypads are cost-effective solutions. At the manufacturing stage, low-cost non-recurring engineering (NRE) makes silicone keypads accessible to a wide range of users, from small startups to large corporations seeking reliable input devices for their products.

The longevity and durability of silicone keypads also contribute to long-term cost savings by reducing the need for frequent replacements or repairs. This makes them a prudent investment for organizations looking to optimize efficiency and minimize downtime.

Are Silicone Keypads Right for the Product You Manufacture?

If you produce consumer electronics such as remote controls, gaming controllers, and wearable devices, you can benefit from silicone keypads. These keypads offer tactile feedback, durability, and customization options that enhance the user experience and differentiate your products in the market.

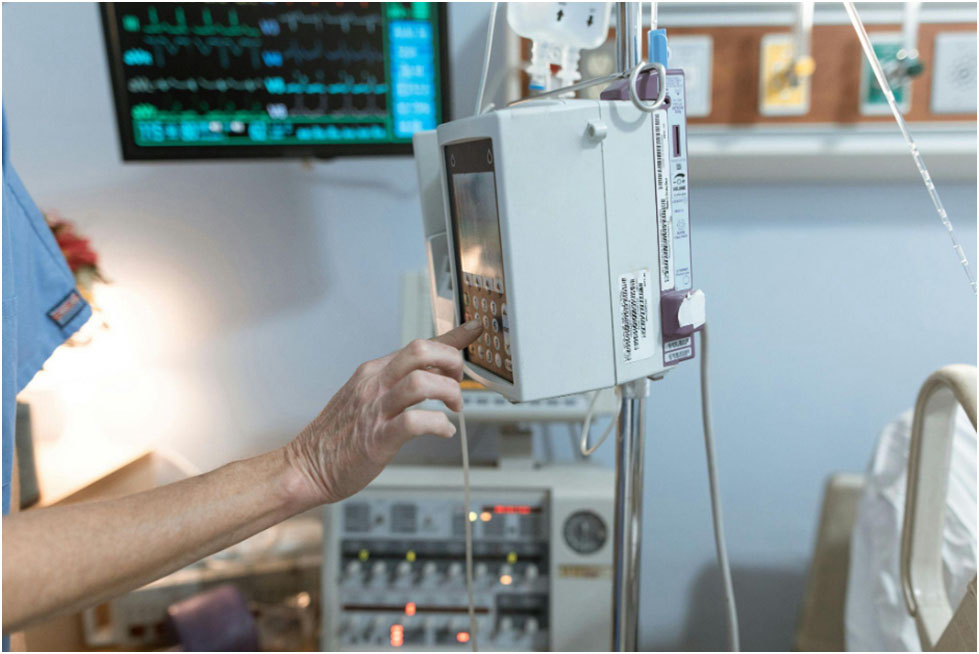

Silicone keypads are ideal for medical devices due to their resistance to temperature and humidity fluctuations, as well as their ability to withstand sterilization processes. Medical device manufacturers can use silicone keypads in equipment such as patient monitors, infusion pumps, and diagnostic devices.

Silicone keypads are well-suited for industrial applications due to their durability, resistance to chemicals and abrasion, and customizable design options. They can be used in control panels, machinery interfaces, and handheld devices used in a variety of industrial settings.

At King Epoxy Emblem Co Ltd, we produce high-quality silicone keypads. Contact us today.