King Epoxy Emblem Co., Ltd »

In-Mold Decoration (IML/IMD)

KTP In-Mold Decorations

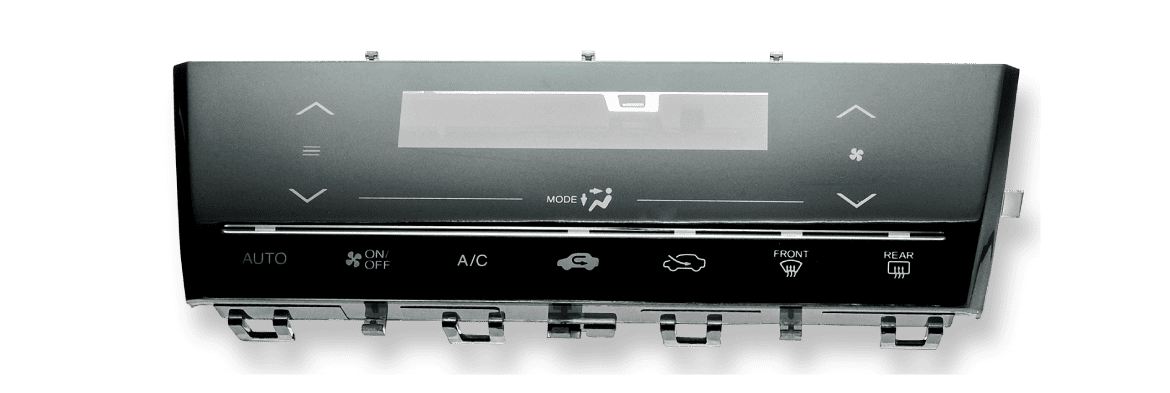

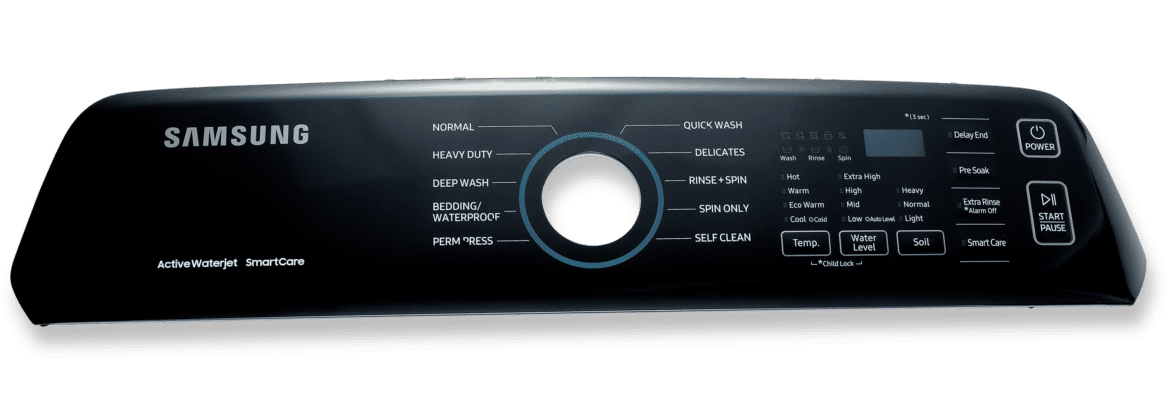

King Epoxy Technology offers In-Mold Labeling (IML), seamlessly integrating graphics with injection-molded plastic for a flawless finish. Our heat or vacuum forming techniques ensure curved shapes wrap around edges, creating visually appealing products without gaps. By combining decorative overlays with the molding process, we enhance graphic durability, reduce manufacturing costs, and offer design flexibility. Graphic overlays serve as the face of a product, providing concise brand identification on controls and capacitive surfaces.

King Epoxy Technology excels in producing high-quality molded plastic control panels with overlays that meet design requirements and aesthetic standards. Our expertise has established us as leaders in button controls, control panels, and membrane switches. Functionality is paramount in control panel design, ensuring ease of use and manipulation. Our experienced engineers collaborate closely with customers to achieve functional excellence and appealing aesthetics. While functionality is crucial, an attractive appearance enhances usability and sparks customer interest.

How In-Mold Decorations are Created

At King Epoxy Technology, creating in-mold decorations is a precise and meticulous process.

Plastic parts are shaped in our injection mold machines, and decorative elements are seamlessly integrated. Precision-cut and formed film with printed graphics is attached to the injection tooling before molding, ensuring smooth and accurate application by our skilled technicians.

We’ve honed our technical expertise to meet the diverse needs of our customers, perfecting the process to ensure graphics are securely attached and sealed, preventing shifting or peeling.

Utilizing a range of high-quality polymers, we form the product’s substrate, tightly bonding the overlay to create a seamless, unified piece.

Following merging the molded product and overlay, each undergoes thorough inspection for quality, appearance, and adherence to customer specifications.